When it comes to labeling in industrial and electrical settings, the materials you choose matter. The wrong label could fade, peel, or become unreadable—compromising safety, compliance, and efficiency. Two of the most common materials used in industrial label manufacturing are phenolic and acrylic.

While both options are widely available, they’re not interchangeable. In this post, we’ll break down the differences between phenolic vs acrylic labels, helping you determine which solution is best suited for your unique application.

What Are Phenolic Labels?

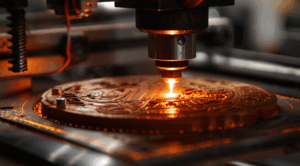

Phenolic labels are made from a composite resin material known as phenol formaldehyde. During production, layers of paper or fabric are infused with resin and heat-cured under pressure to form a rigid, non-conductive sheet. The final result is laser- or rotary-engraved to produce long-lasting engraved labels.

Phenolic labels are widely used in electrical applications for their:

- Non-conductive properties

- Resistance to heat and flame

- Ability to withstand chemicals and solvents

- High durability in outdoor and industrial settings

At Mike’s Trophies, we specialize in phenolic panel engraving tailored for high-risk environments.

What Are Acrylic Labels?

Acrylic labels are manufactured from plastic (typically PMMA or similar polymers) and often used for general signage, identification tags, and indoor labeling. While they can be engraved, acrylic tends to be more lightweight and flexible.

Advantages of acrylic labels include:

- Variety of color options and finishes

- Lightweight design

- Cost-effective for less demanding environments

- Easier to cut or shape for decorative uses

Phenolic vs. Acrylic Labels: Feature Comparison

Let’s compare the two materials across key categories:

| Feature | Phenolic Labels | Acrylic Labels |

| Heat Resistance | High – tolerates extreme temps | Moderate – may warp or discolor |

| Electrical Insulation | Excellent – non-conductive | Poor – not suited for live circuits |

| Chemical Resistance | Strong – resists acids, solvents | Limited – prone to staining/degradation |

| Durability | Very high – industrial-grade rigidity | Moderate – best for indoor use |

| Engraving Detail | High contrast, deep engraving | Good contrast, shallower depth |

| Cost | Slightly higher upfront | More affordable for low-risk uses |

| Best Use | Electrical panels, safety signage | Office signs, decorative nameplates |

When Should You Choose Phenolic Labels?

If you’re labeling equipment in a facility where:

- Heat, moisture, or chemicals are present

- Electrical insulation is required

- Labels must remain intact for years

- Safety compliance (OSHA, ANSI) is a concern

…then phenolic labels are the clear winner. Their ruggedness ensures that critical information remains visible and intact long after adhesive or plastic options fail.

When Are Acrylic Labels a Better Fit?

Acrylic labels may be a smart choice for:

- Decorative signage

- Low-impact office use

- Short-term applications

- Aesthetic-first projects (e.g., ADA signage)

They’re easier to work with for curved or non-standard surfaces and offer more finish options.

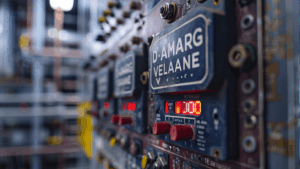

Real-World Example: Industrial Electrical Panel

Imagine you’re marking circuit breakers and power disconnects in a factory floor control room. You need a label that:

- Won’t melt near hot equipment

- Stays legible after chemical cleanings

- Meets OSHA requirements

Acrylic would fail quickly. Phenolic would last for decades.

That’s why professionals rely on our engraved phenolic tags at Mike’s Trophies — for solutions that endure.

Can You Customize Both?

Yes, both phenolic and acrylic labels can be customized for:

- Size and shape

- Mounting method (adhesive, screw holes)

- Color contrast

- Text engraving

However, phenolic tags allow for deeper engravings that resist fading over time, making them more suitable for high-traffic and harsh environments.

How to Choose Between Phenolic and Acrylic

Use this simple guide:

- Industrial + Outdoor + Electrical = Phenolic

- Indoor + Decorative + Low-Risk = Acrylic

Need help choosing the right material? Reach out to us and we’ll walk you through the best solution based on your specs.

Final Thoughts

Choosing between phenolic vs. acrylic labels depends on the demands of your application. For high-performance, long-term durability in electrical and industrial environments, phenolic is the superior choice. For light-duty, decorative, or budget-friendly projects, acrylic may do the trick.

If your labels need to do more than just look good — if they need to survive, protect, and communicate clearly — trust Mike’s Trophies to deliver precision-engineered engraved labels that won’t let you down.

Ready to Order?

Get custom industrial labels tailored to your environment. Whether you need phenolic labels for an electrical panel or acrylic tags for a front desk sign, Mike’s Trophies has the expertise and technology to help.Contact us today for a free quote and let’s label smarter.