Phenolic labels are known for their toughness, durability, and ability to endure even the most hostile industrial environments. But have you ever wondered how these small, simple-looking tags are actually made?

Understanding the phenolic engraving process helps explain why these labels are trusted by electricians, engineers, manufacturers, and facility managers nationwide.

In this post, we’ll walk through the step-by-step process of producing engraved phenolic tags, highlighting what makes them so resilient and effective.

What Is Phenolic Material?

Phenolic is a type of thermosetting plastic created by layering paper or fabric with phenolic resin and then curing it under heat and pressure. The result is a rigid, dense material that:

- Resists heat and flame

- Repels moisture and chemicals

- Is naturally non-conductive

- Holds engravings with long-term clarity

It’s the ideal substrate for durable industrial labels, especially in electrical and mechanical environments.

At Mike’s Trophies, we use only high-grade phenolic sheets to ensure our labels are up to code and built to last.

Step 1: Selecting the Phenolic Sheet

Phenolic sheets come in a variety of:

- Thicknesses (typically 1/16″, 3/32″, or 1/8″)

- Core colors (white, black, yellow, red, etc.)

- Top laminate colors for contrast

These two-tone sheets are what allow for highly visible engraved text — when the top layer is removed, the contrasting core color is exposed.

Step 2: Designing the Label Layout

Next, the label layout is created digitally. This includes:

- Desired text

- Symbols or arrows for direction

- Standard sizing or custom dimensions

- Placement of mounting holes or adhesive cutouts

Layout software ensures precise spacing, alignment, and consistent sizing — especially critical for large batch orders.

Want to include your own part numbers or serialized tags? Contact our team and we’ll handle custom layouts from your file or spec sheet.

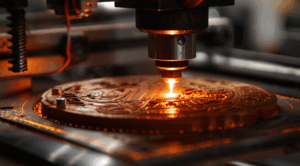

Step 3: Engraving the Phenolic

Once the layout is finalized, it’s sent to the engraving machine. We use both:

- Rotary engraving for deeper cuts and thick material

- Laser engraving for precision and clean contrast

The engraving process removes the top layer of phenolic, exposing the contrasting color beneath. This creates text and graphics that:

- Won’t fade

- Won’t rub off

- Stay readable for years

Step 4: Cutting and Shaping

After engraving, the labels are cut to size using:

- Laser cutting for complex shapes

- Shears or routers for rectangles and squares

If the label requires mounting holes, those are drilled or punched at this stage. Labels can also be cut with rounded corners to reduce chipping.

Step 5: Finishing Options

Depending on the application, the label may be finished with:

- Adhesive backing for peel-and-stick installation

- Drilled holes for screw mounting

- Beveled edges for a professional appearance

- Zip-tie slots for attaching to wiring bundles or conduits

We can also serialize your tags or group them into kits for installation teams.

Why This Process Matters

The detailed phenolic engraving process ensures that labels can:

- Survive extreme temperatures in electrical rooms or engine compartments

- Withstand chemical cleaning agents used in labs or food processing

- Stay readable for years in outdoor environments exposed to UV and moisture

- Meet safety codes required by OSHA, NFPA, and ANSI

Unlike printed stickers, which degrade over time, engraved phenolic tags are engineered for permanence.

Applications for Engraved Phenolic Tags

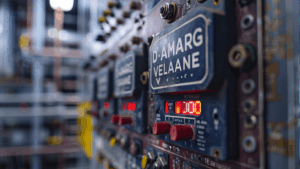

The end result? A rugged, professional-grade label that’s ideal for:

- Electrical panels

- Disconnect switches

- Control boxes

- Industrial machinery

- Hazard zones

- Equipment IDs

Need help designing a label for your application? Our experts can help with layout, sizing, and durability requirements.

Final Thoughts

Now that you understand the full phenolic engraving process, you can see why these labels are trusted in demanding fields like manufacturing, energy, and healthcare.

At Mike’s Trophies, we provide full-service label design and engraving — from material selection to final cut. Every tag is engineered to be durable, legible, and built for the long haul.

Get a Custom Phenolic Label Quote

Need custom engraved phenolic tags for your facility or equipment? We’re ready to help. Reach out to Mike’s Trophies For expert advice, fast turnaround, and top-quality engraving.