Phenolic labels are trusted across industries for their durability, safety, and clarity—but even the highest-quality label won’t perform properly if it’s poorly installed. Improper mounting or environmental exposure can lead to warping, detachment, or loss of legibility over time.

In this guide, we’ll walk through everything you need to know about installing phenolic labels the right way, along with maintenance tips that ensure your engraved tags stay clear and secure for years.

Why Installation Matters

Phenolic labels are tough, but they aren’t indestructible. A misaligned label, weak adhesive, or incorrectly drilled tag can:

- Crack under pressure

- Detach from mounting surfaces

- Become unreadable due to vibration or exposure

- Fail to comply with OSHA or ANSI standards

Whether you’re mounting a control panel tag, pipe marker, or safety signage, proper installation preserves the label’s purpose—and protects your team.

Choosing the Right Mounting Method

There’s no one-size-fits-all when it comes to mounting phenolic tags. Your choice depends on:

- The environment (indoor vs. outdoor)

- Surface material (metal, plastic, concrete, etc.)

- Exposure to heat, moisture, vibration, or chemicals

- Temporary vs. permanent labeling needs

Here are the most common and effective mounting options:

1. Adhesive Backing (Peel-and-Stick)

Best for: Smooth indoor surfaces (equipment casings, painted walls, cabinets)

- Use industrial-grade adhesives like 3M VHB tape or foam-backed options

- Clean the surface thoroughly before application

- Apply firm pressure to eliminate air bubbles

- Avoid using adhesives in high-heat or outdoor environments

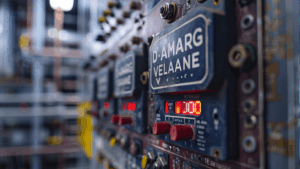

2. Mechanical Fastening (Screws, Rivets, or Bolts)

Best for: Permanent, outdoor, or vibration-prone environments

- Drill clean mounting holes into the phenolic label and surface

- Use stainless steel screws or rivets for corrosion resistance

- Be cautious with torque—over-tightening can crack the material

- Add washers if mounting on uneven surfaces

This is the most secure method for mounting engraved labels on control panels, junction boxes, and outdoor installations.

3. Zip-Tie Mounting or Wire Tags

Best for: Cable bundles, conduit pipes, valves, and temporary setups

- Request pre-slotted phenolic tags

- Use nylon or stainless steel zip ties for secure placement

- Ensure tags don’t slide or rotate after installation

- Choose rounded corners to prevent abrasion or catching on nearby wires

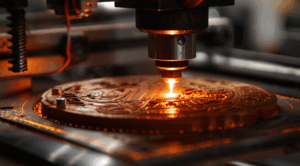

Mike’s Trophies offers custom-cut tags with slotted or drilled mounting options for any surface or object.

Tips for Proper Label Alignment

- Use a level and ruler to ensure straight, aligned installation

- Measure twice—especially for grouped labels

- For equipment with multiple labels (e.g., breakers or control panels), standardize spacing and height

- Use layout templates for batch installs

A clean layout improves both aesthetics and functionality—especially during troubleshooting or emergency situations.

Environmental Considerations

When installing labels outdoors or in harsh environments, keep these factors in mind:

- UV Exposure: Use phenolic material with UV-resistant coatings or deeper engraving to prevent fading

- Chemical Splash: Avoid mounting with adhesives that can degrade over time; opt for mechanical fastening

- Moisture: Seal holes with silicone or rubber washers when mounting on outdoor equipment

- Extreme Heat: Use thermally stable adhesives or materials rated for high-temperature applications

Maintaining Phenolic Labels

Phenolic labels are incredibly low-maintenance—but some care goes a long way:

1. Routine Cleaning

- Wipe labels with a soft cloth and mild detergent

- Avoid abrasive cleaners that can damage engraved surfaces

- Rinse with clean water to remove chemical residues

2. Inspect for Wear and Damage

- Schedule inspections as part of your maintenance plan

- Look for cracks, fading, or label detachment

- Replace damaged tags immediately to stay compliant

Contact us for fast reorders of matching engraved tags.

When to Replace a Label

Even the most rugged labels have a lifespan. Replace phenolic labels if:

- The engraving is no longer legible

- The label has cracked or warped

- The tag detaches or slides from its mounting

- Safety or equipment information changes

Final Thoughts

A quality phenolic label deserves a quality installation. Whether it’s mounted on a control panel, cable bundle, or outdoor junction box, following proper mounting techniques and maintenance practices ensures your labels do their job—and do it well.

At Mike’s Trophies, we provide custom phenolic tags in any shape, size, and mounting configuration you need. Every label is precision-engraved, cut to order, and designed to withstand the toughest conditions.

Ready to Order Custom Phenolic Labels?

Get it right the first time with durable phenolic tags from a trusted source. Request your quote from Mike’s Trophies and we’ll help you plan labels that are easy to install and built to last.