When it comes to labeling in demanding industrial settings, durability isn’t optional — it’s essential. Heat, chemicals, moisture, and abrasion can quickly degrade standard labels. That’s why custom phenolic labels are the go-to solution for companies needing long-lasting identification in tough conditions.

In this article, we’ll explain how to design durable industrial labels that perform under pressure, and why phenolic is the ideal material for harsh environments.

Why Durability Matters in Industrial Labels

A label that peels, fades, or discolors isn’t just a cosmetic issue — it’s a safety hazard. In electrical, chemical, or mechanical settings, worn labels can lead to:

- Misidentification of circuits or parts

- Non-compliance with safety codes

- Delays in maintenance or repairs

- Potential injury or equipment failure

To avoid these problems, you need a label that stays readable and intact over time, no matter the environment.

Why Choose Phenolic Material?

Phenolic resin is a thermoset plastic that’s chemically bonded under heat and pressure. This process creates a dense, rigid material that offers:

- High temperature resistance (up to 500°F)

- Chemical resistance to acids, solvents, and oils

- Non-conductive and flame-retardant properties

- Water and UV resistance

- Structural rigidity for long-term installation

These properties make engraved phenolic tags ideal for labeling in:

- Electrical panels

- Refineries and chemical plants

- Outdoor utility enclosures

- Factory automation systems

At Mike’s Trophies, we manufacture custom phenolic labels that perform where others fail.

Key Factors in Designing Durable Phenolic Labels

Designing a label that lasts isn’t just about choosing the right material — it’s about optimizing every detail:

1. Choose a High-Contrast Color Combo

For visibility and readability, select combinations like:

- White text on black background

- Yellow on black (for caution/safety zones)

- Black on white (for clean interior environments)

These combinations improve legibility even when dust, grease, or shadows are present.

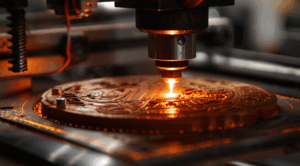

2. Use Deep Engraving

Laser engraving should be deep enough to resist wear from cleaning, abrasion, and environmental exposure. Unlike printed labels, engraved phenolic tags won’t fade or rub off.

3. Specify the Right Thickness

Standard thickness ranges from 1/16” to 1/8”. Thicker tags provide more durability and rigidity — especially important for outdoor or mobile installations subject to vibration.

4. Select the Right Mounting Option

Phenolic labels can be:

- Drilled for screw mounting

- Applied with industrial adhesive backing

- Slotted for zip-tie attachment

For harsh environments, mechanical fastening (e.g., screws or rivets) is often more secure than adhesives, which may weaken over time.

5. Include Functional Design Elements

Labels should be designed with usability in mind:

- Rounded corners prevent cracking

- Clear fonts improve readability

- Standardized symbols assist multilingual teams

- Arrows or directional indicators help in troubleshooting

Need help designing layout or text? The team at Mike’s Trophies can guide you through industrial labeling best practices.

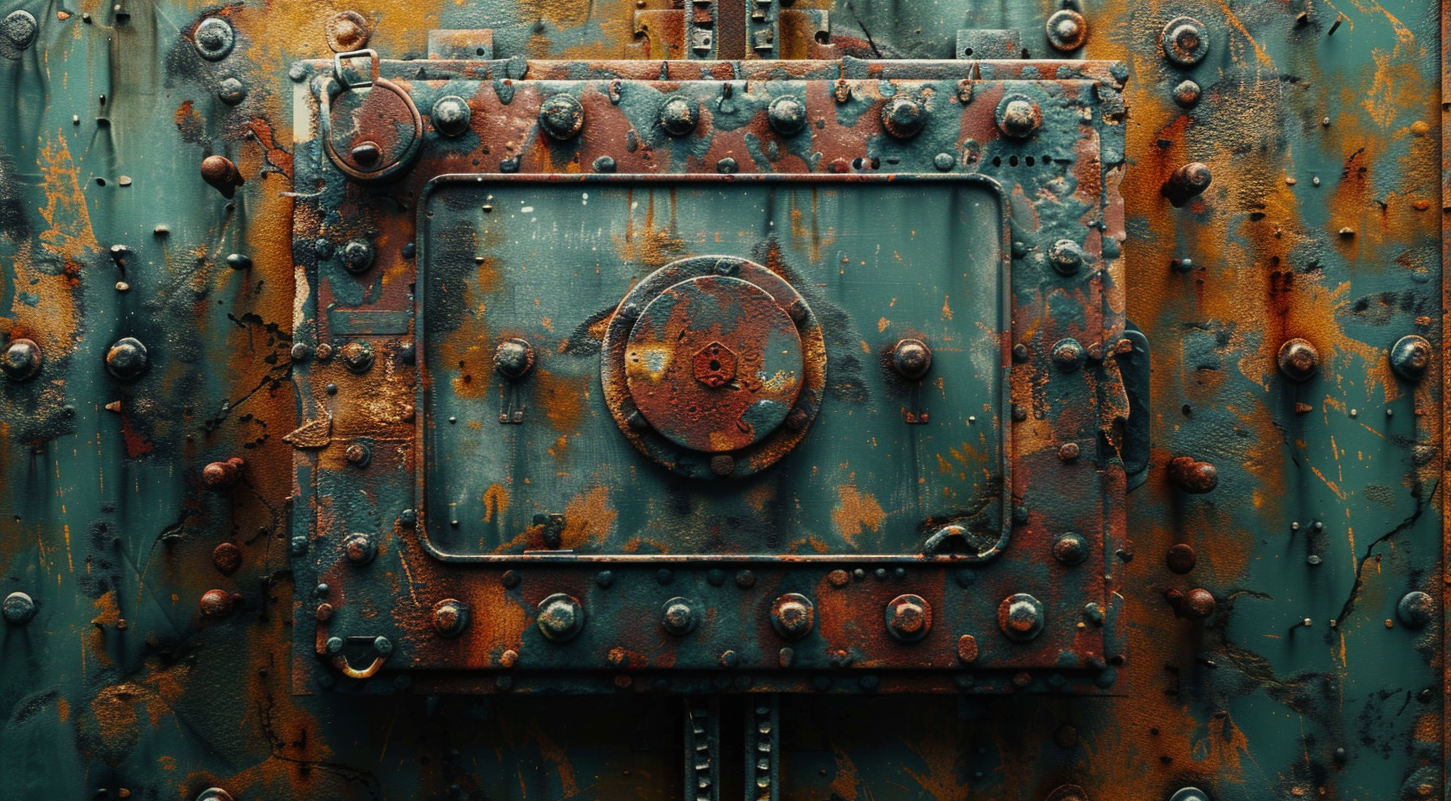

Environments That Demand Phenolic Labels

Let’s look at where durability is truly tested:

Chemical Processing Plants

Labels must resist acids, caustics, and solvents during regular wash-downs and spills.

Outdoor Installations

Rain, snow, wind, and UV rays degrade most materials—but phenolic stays intact.

High-Heat Areas

In proximity to furnaces, generators, or switchgear, labels must endure elevated temperatures without warping or fading.

Marine and Offshore

Saltwater exposure and constant movement demand corrosion-resistant and rugged mounting.

Customization Options for Maximum Performance

When ordering your phenolic labels, consider:

- Font size and spacing for readability

- Custom cutouts or shapes for tight spaces

- Serialized or numbered engraving

- Two- or three-ply material layers for contrast and rigidity

Mike’s Trophies provides full customization to meet your exact application needs.

Don’t Let Labels Be the Weak Link

In critical environments, label failure leads to safety failure. The durability of custom phenolic labels makes them an investment in operational efficiency, regulatory compliance, and worker safety.

Trust the experts at Mike’s Trophies to produce labeling solutions built for the long haul.

Final Call to Action

Ready to improve safety and clarity with long-lasting industrial labels? Whether you need custom tags for heat, chemical exposure, or outdoor use, Mike’s Trophies has you covered.Request your custom phenolic label quote today and get durability you can count on.